Inspect new or reconditioned part to be processed

Confirm all processing details and coating formulae

Strip & repair as necessary to OEM spec minus coating specification

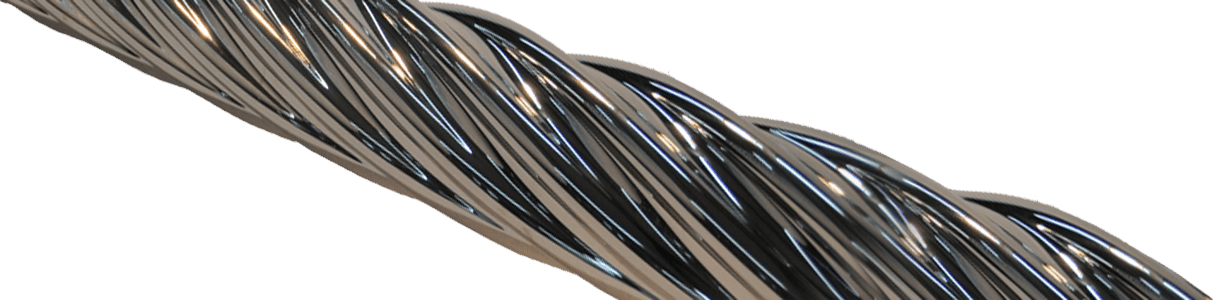

Prepare the surface via grit blast

Application of the coating via HVOF

Sprayed and sealed – application dependent

Finish polishing with diamond abrasive

Inspect and measure

Part complete with mirror finish

Key Points:

Our process has key elements to obtain the desired specifications and high quality standards:

- 100% QA inspection of received parts to confirm the correct pre-coating dimensions are correct, tool marks removed, coated area matches drawing, materials of construction, hardness and confirming formula match.

- QC Measurement of parts before and after each step ensures quality throughout the process to meet the desired coating specification.

- Precise control and calculation of the powder formula deposition rate based on the part and solution to reach desired machine part specification (+ 0/-.002” (.0508 mm).

- Methodical combination of rotation and traverse speed to control heat input and deposition rate of selected coating formulation to minimize internal stresses.

- Post coating heat straightening to meet industry/drawing requirements for TIR

- Consistent monitoring of the polishing system to ensure product meets QC dimensional data desired to pass final inspection.