The Problem:

A blown film producer of custom and engineered blends sees loss of film properties and surface appearance from a small amount of wear. A particular process makes foamed MW PE and wear of the screw mixer leads to temperature differences, poor mixing and surging at the die interface. As these are high performance liners, consistency of output and process stability are extremely important for high quality products.

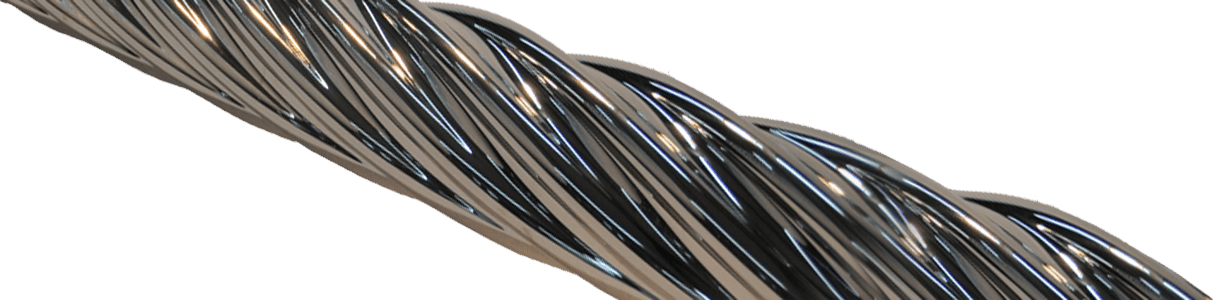

This process uses a 4-1/2” 24:1 extrusion screw with double mixers and Colmonoy 56 hard facing with chrome plating. This screw configuration is the customers own design. The polymer is filled with TiO2 in concentrations from 4-5% and a maximum of 6% regrind is reintroduced to the system. It is not uncommon to see OD wear of .020”-.025” (0,5– 0,6 mm) in 12—18 months of operation. Product quality, not output rate, determines when a screw requires replacement. Output is reduced less than 10% when product quality begins to suffer due to temperature variation.

The Solution:

Extreme Coatings provided their XC1000 tungsten carbide coating at .010” (0,25 mm) thickness with a mirror polish finish. This screw was installed May 2006 and immediately melt temperatures dropped and output increased. This product line had a large production backlog and it would be at least a year before the screw was measured.

Benefits:

Estimated output gains from a carbide coating are presented in the table.

| Month 18 | ||

|---|---|---|

| Current Screw | 3,682,800 | Total LB. |

| Carbide Screw | 3,846,960 | Total LB. |

| Difference | 164,160 | LB. |

| Sell Price/LB. | $1.25 | $205,200 |

The comparable wear rate is taken from our ASTM G-65 test data for Colmonoy 56. Output reduction is 30 LB./hr. over 18 months and sell price of output of $1.25/LB.

Twenty eight to 36 months represents double life in this process. Comparative wear life of XC1000 over Colmonoy 56 is five times which indicates the screw will reach the end of the coating (.020”, 0,5 mm) in 60 to 80 months.

Not only will this screw last longer and provide more process stability it will produce more sellable product over its service life than the previous feed screw.