Biofouling Subject

Micro and macro-biofouling of underwater components has been a challenge to the Maritime Industry for thousands of years. Over 2,000 species of plankton, including barnacles, search for homes amongst the seashores and floating objects in the sea. Attachment to the running gear and hulls of all types of boats is an unfortunate favorite home for plankton. Great effort must be made for the prevention of such growth.

The Problem

Millions of dollars annually are spent on cleaning and recoating underwater components. Hard and ablative paints, polymer coatings and other roll on or spray on antifouling protection systems are slowly removed by cleanings and/or abrasion/cavitation. The antifouling performance of these coatings is adequate however, demand is high for more effective antifouling systems that retain their integrity over a longer period of time.

The Solution

Non-Ablative Advanced Ceramic Antifouling Coating (AC2)

Pyro-augmented particulate spray (PAPS) of advanced ceramic antifouling coating (AC2). The coating is applied via a patent pending method by which hard, ceramic antifouling powder (AC2) is introduced into a high temperature jet stream, whereby the particles are plasticized and subsequently sprayed onto a prepared metallic surface. The result is an abrasion and erosion resistant antifouling surface with bond strength in excess of 5,000 psi. Subsequently, the coating is treated utilizing a biocide saturated capillary sealer to impregnate micro-porosity preventing substrate corrosion.

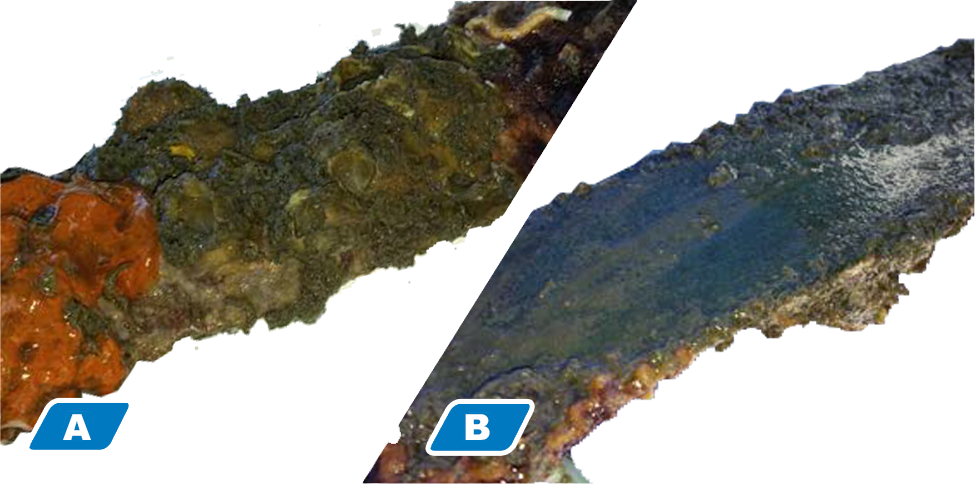

A – Uncoated side after 18 months.

B – Coated side after 18 months.

Coating Attributes

Hard abrasion and scratch resistant, corrosion resistant, erosion resistant, non-ablative, non-leaching, can be wire brushed and lightly sanded without removal.

Applications: Propellers, drive shafts, trim tabs, stabilizers, raw water intakes, seacocks, bow thrusters, rudders, ballast tanks, underwater hydraulic actuators, sea buoy floats, power plant intake/outlet grates, sea walls, piling protectors, anything in or under seawater.