Once processors have experience with our carbide coatings to protect feedscrews from abrasion and corrosion, they often ask if we can coat other wear items in their process. This has resulted in our Cushion Master carbide protecting non-return valves, Ultrasonic Welding Horns, ejector pins, mold surfaces, polymer gear pumps, pneumatic conveying tubing, etc. We have developed solutions for all of these items, some very successful and some less so. We are open to helping find solutions to whatever issue you may have.

We coat feedscrews for a number of processors that extrude PVC through pipe and sheet dies. As PVC degrades, hydrochloric acid can result which corrodes steel and removes chrome plating.

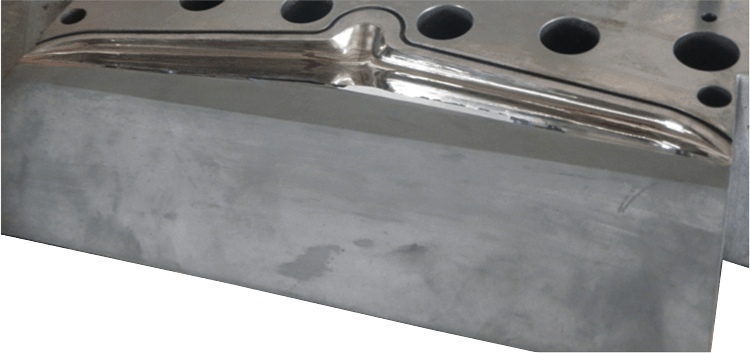

In coat-hanger or siding dies, PVC degrades and builds up at the outward flow path of the die. This leads to frequent disassembly and cleaning, which shortens die life and results in the need for more frequent refurbishment.

We are working to help solve this corrosion problem with thermal spray coating. Our finished layer has very low porosity, which results in very high corrosion resistance. This polished surface resists material build-up and the hard particles will not scratch with aggressive hand cleaning.

The goal of this project is to at least double the time between complete refurbishment of dies and to reduce the need for frequent disassembly for cleaning.