The Problem:

This customer makes consumer products for the Lawn and Garden industry. Economics of operation has lead to much of their production activity being moved to lower cost countries. This plant countered the trend by making better quality finished products (longer life) at a lower cost than the offshore site.

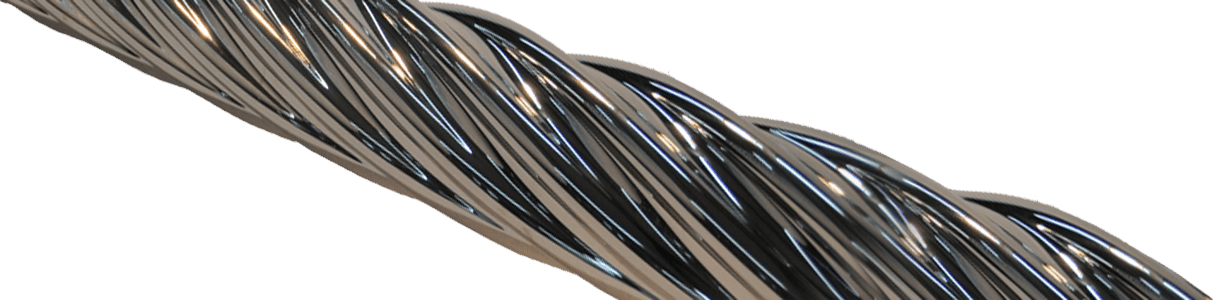

They process a 33% glass filled nylon material making structural engine housings. These parts require strength and heat resistance. This is a large part approximately 2-1/2 to 3 lbs shot size on an 80 mm 18:1 feed screw. Cycle times are about 1 minute which means polymer residence time is very short and with a nylon material this can contribute to more rapid wear.

Past 80 mm GP screws were hard faced with Colmonoy 56 and hard chrome plating. At six months of 24/7 operation these screws had as much as .030” of OD wear. Root wear and flight side erosion were also evident which made screw rebuilds uneconomical.

The Solution:

Extreme Coatings encapsulated an 80 mm, 18:1 feed screw with .010” of XC1000 tungsten carbide (.020” overall). This screw was installed in a carbide lined barrel and operated around the clock for 2-1/2 years until process issues caused it to be removed.

Benefits:

The coating was worn through on the OD in the transition section and metering zones of the screw. No flight side erosion was evident and the screw could be stripped of coating and the OD rebuilt.

This was nearly a five-fold increase in wear life compared with the previous screw protection. This process used to operate 24/7 making about 8500 units per day. The production manager credits his equipment condition for helping keep this site as competitive as their off-shore operations.