Super-wear-resistant tungsten carbide coatings for feedscrews and other process parts will be highlighted

St. Petersburg, FL USA – September 10, 2019

The K-Show in Dusseldorf, Germany is the biggest tradeshow for the plastics industry, and Extreme Coatings will be there celebrating 23 years serving the plastic and rubber industries. At the K-Show Extreme Coatings will present their full range of products and services, but the highlight of their exhibit will be the newest improvements in their CarbideX Coating Technology for replacement of nitriding and chrome plating on conical and parallel twin feedscrews. This improved technology was prompted by environmental concerns with chrome plating and the need for better protection against wear and corrosion.

The exhibit will educate visitors on wear resistance and the team will explain how Extreme Coatings can help companies achieve two to five times longer equipment life. Samples of CarbideX formulations (C1000, C2000, and C9000-nano) of tungsten and chromium carbide encapsulation will demonstrate the range of wear-resistance capabilities on a variety of components, including single screw injection molding and extrusion screws, twin extrusion screws, continuous mixing rotors and other parts in the plasticizing process.

Extreme Coatings provides enhanced alternatives to chrome plating, nitriding and other surface treatments. Often these other treatments don’t offer enough protection to be as effective as possible. Unlike chrome plating, Extreme Coatings’ CPR (Chrome Plating Replacement) is virtually nonporous, so corrosive gasses from PVC cannot attack the base of the screw. Unlike nitriding, CPR adds corrosion resistance as well as greatly increased wear resistance.

CPR is also more environmentally friendly than chrome plating. CPR uses C4000, a chromium carbide compound. Chromium (Vi) as used in chrome plating is a known carcinogen, but Chromium (III) compounds used in CPR’s C4000 are not known to be carcinogenic or toxic.

In some applications where abrasive fillers cause premature wear, Extreme Coatings’ C1000 or C9000 nano formulations of tungsten carbide encapsulation will provide superior wear resistance combined with a high level of corrosion resistance – minimizing wear and maximizing profit.

Extreme Coatings’ approach is to analyze specific wear or corrosion problems and then customize the solution to maximize component life. Curt Kadau, President of Extreme Coatings, explains, “Advancements in polymer technology demand parallel advancements in feedscrew and processing technology. Extreme Coatings has kept pace with these advancements and will continue to develop new products to meet the demands of our customers.”

The K Show will be held October 16 – 23 in Dusseldorf, Germany. Extreme Coatings will be exhibiting in Hall 13, Stand B91-6.

Contacts

Scott Caplan EVP

(O) 727-528-3734 x122

scottc@extremecoatings.net

Engineered Surfaces to Extend Service Life and Performance

-

HVOF Thermal Spray

HVOF Thermal Spray Extreme Layer of Protection

Extreme Layer of Protection High Performance Formulas

High Performance Formulas -

Oil and Gas Industry

Reduce Replacement Costs for Mud Rotors

Reduce Replacement Costs for Mud Rotors

HVOF CPR delivers more abrasion and corrosion resistance than hard chrome plating (HCP) - even in high chloride environmentsRead More -

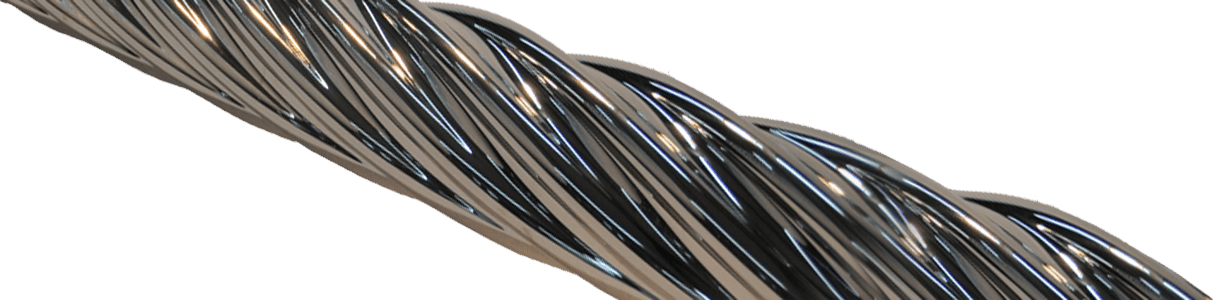

Read MoreTwin Feedscrews

Our high percentage carbide layer can provide from two to four times more wear life depending on fill loading. Plastic Injection Molding

Plastic Injection Molding

-

Single FeedscrewsRead More

Feedscrews

Feedscrews

Our coatings are perfect for injection molders and extruders when processing fiberglass, calcium carbonate, titanium dioxide and metals, ceramic or other highly abrasive fillers. -

Mixer-Extruders

Continuous Mixing Rotors

Continuous Mixing Rotors

Our C1000 tungsten carbide has been used as chrome replacement in aggressive applications. C1000 doubles the working life of rotors compared to hard chrome plating.Read More

Leave a Reply